Energy consumption is the most important single cost factor in wastewater plants. Comparing each

element of your plant to key performance indicators is critical to understand whether you are spending too much on your energy bill!

The EU's ENERWATER initiative is developing an innovative standard energy audit methodology, allowing the detailed estimation of energy consumption, including

KPIs, a wastewater treatment energy index (WTEI) and energy labels.

A team of scientists from ENERWATER has written an article on this project which we're offering exclusively to our customers.

Click here to download ENERWATER's white paper.

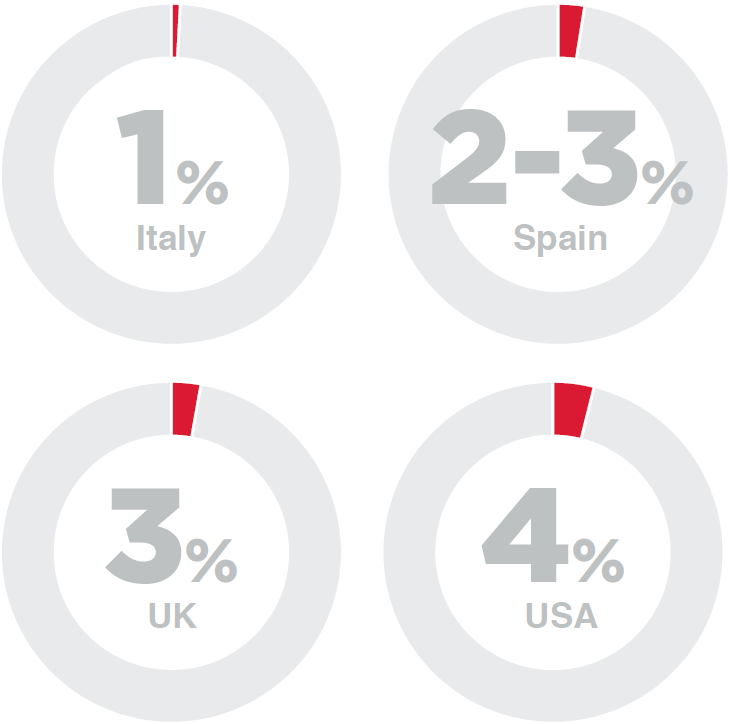

HOW MUCH OF A COUNTRY’S ENERGY COSTS GO INTO WASTEWATER TREATMENT PLANTS?

LEARN MORE ABOUT...

- Key performance indicators for each stage of your process

- Energy audits

- How to calculate your equipment's energy consumption

- How you compare to key benchmarks

- Crucial KPIs for your business

TREATMENT STAGE CLASSIFICATION

The following stages were used to disaggregate the energy consumption data:

Stage 1:

Preliminary treatment, which includes the raw wastewater pumping station, as well as equipment involved in

screening, grit removal, oil separation, flow equalization, storm water equalization and pumping.

Stage 2:

Primary treatment covers all equipment involved in primary sedimentation, including pumps for primary sludge extraction and chemical doses.

Stage 3:

Secondary treatment, which includes all the processes and the equipment required for biological

wastewater treatment.

Stage 4:

Tertiary and advanced treatment, which includes a wide variety of chemical, physical and biological processes and equipment.

Stage 5:

Sludge treatment, which includes thickening, dewatering, sludge stabilisation and thermal process.

Stage 6:

Return liquors treatment can include processes for treatment of rejected water usually focused

on nitrogen and phosphorus removal.

Stage 7:

Odour treatment, which includes recovery and treatment of extracted air from sludge processing

technologies.

The Horizon 2020 ENERWATER project is to develop, validate and disseminate an innovative standard methodology

for continuously assessing, labelling and improving the overall energy performance of Wastewater Treatment Plants.

For that purpose ENERWATER developed a collaborative framework in the water treatment sector including research groups, SMEs, water management companies, city councils, water

authorities and industry.

To learn more go to www.enerwater.eu

Authors:

- B.M. D’Antoni and F. Fatone, Department of Biotechnology, University of Verona, Italy

- L. Stefani and E. Parelli, ETRA S.p.A., Progetti Innovativi Ricerca e Sviluppo, Padua, Italy

- A. Hospido and S. Longo, Department of Chemical Engineering, Unversity of Santiago de Compostela, Spain

- A. Soares, Cranfield Water Sciences Institute, Cranfield University, UK